Enterprise Point of Sale: Transforming Multi-Store Retail Operations

Managing a multi-location retail business brings a host of challenges. From keeping operations streamlined across…

Read More >>

If you operate a B2B business, customer service is a strategic cornerstone, not just a cost center.

This is why a warehouse management system (WMS) is crucial. Warehouse management tools automate fulfillment and messaging. They keep your B2B customers informed, and ultimately, enable your business to build trust and loyalty.

Think about it like this:

Your customers rely on you for the wholesale products they sell. And their customers expect the shelves to be stocked and their orders to be fulfilled fast. Automating customer service tasks in your WMS updates them every step of the way.

Interested in how it works? Keep reading to learn how warehouse management systems automate inventory tasks and fulfillment, helping you provide better B2B customer service.

B2B (business-to-business) warehouses help with the smooth functioning and streamlining of B2B operations. Hence, they play a critical role in the supply chain as it serves as:

In other words, a B2B warehouse sets the stage for commerce. Inefficiencies at the warehouse level, affect the entire supply chain. And this causes a cascade of issues faced by the in-house sales and support team, all the way down to retail customers.

Unfortunately, B2B warehouses face several challenges that can impact their efficiency. These are some of the most common challenges faced by B2B warehouses.

Controlling operating expenses is time consuming. Warehouse managers need to balance labor, maintenance, utilities, and technology costs, to name a few.

Because it’s so time-consuming, this makes it even more challenging to deliver quality service. It’s a never-ending task. As a result, service suffers, as managers have to make due with fewer resources.

The market expects fast shipping: Same-day service, overnight shipping, and two-day options have become the expectation. But that’s not just on the consumer side anymore.

B2B customers (often retailers) expect it too, as they seek to keep up with online shopping demand. Automation is a necessity for meeting tight delivery deadlines, while maintaining accuracy.

B2B warehouses frequently handle 1000s of SKUs. And all of the inventory tasks are time consuming: Maintaining and tracking stock levels, managing inventory accuracy, and timely replenishment.

A warehouse management system offers a solution.

For B2B warehouses, it is crucial to have accurate and timely order fulfillment. This includes:

One of the biggest challenges of B2B warehouses is to ensure order fulfillment accuracy, and technology is often the tool that makes this possible.

Lack of real-time visibility can disrupt the entire supply chain. B2B warehouses may need real-time inventory visibility to avoid difficulties. Supply chain visibility depends on various channel partners, such as manufacturers, courier companies, delivery agents, etc.

B2B warehouse management systems (WMS) are essential in streamlining the warehouse’s operations. These software solutions are designed to manage and control warehouse operations, ensuring accuracy, efficiency, and supply chain visibility.

Here’s a detailed guide to a B2B warehouse management system and how it works:

B2B warehouse management tools manage and control warehouse operations for businesses. They ensure smooth B2B transactions and higher efficiency.

A WMS acts as a centralized platform to handle various warehouse tasks, track inventory, process orders, supply chain visibility, and much more.

Here are a few key features that you should look for:

Your warehouse staff will be unable to quickly accommodate customers if the foundational aspects of your warehouse management aren’t in place. Properly tracking your warehouse inventory is the cornerstone of this foundation. Using an SKU system, your warehouse management software will monitor the stock levels of all items and pinpoint the exact location of each item within your warehouse facility.

The tracking system will also show you which items are in transit from manufacturers and to your business customers. When your customers call the warehouse to learn the ETAs of recent orders or to report that an expected order has not arrived, your warehouse workers must be able to access all information associated with those orders.

Your warehouse workflow could get congested if you don’t maximize and fully utilize your shelf space. Often, visualizing how to pack and store goods on your own won’t result in getting the most storage space out of every aisle in your warehouse.

Considering the following suggestions, you can increase the volume of goods per square foot of shelf space.

Remember, your warehouse and inventory management software must accurately reflect your warehouse floor and workflow, no matter how complex it becomes as you grow.

Receiving and stowing refers to your incoming inventory that must be recorded and shelved adequately at your warehouse. Your warehouse management and inventory software must reflect the real-world flow of items that come and go.

To accurately record incoming inventory, the software must be able to track freight as it comes in from trucks across your loading docks. Whatever happens in real life must be reflected within the software, including discrepancies.

Suppose a worker discovers that a package of incoming goods has fewer units than expected. In that case, the worker must be able to alert you on the spot and update the entire system quickly without fanfare, so that you can immediately contact any of your customers who could be affected.

Your warehouse management software must assist your workers with the two most often-used core functions within the supply chain: picking and packing. First, the networked software must be capable of generating pick lists for your workers.

Using a pick list, the worker will know the exact location of each item within the warehouse and retrieve all items for the order quickly and efficiently. This should encompass zone picking, wave picking, and batch picking.

The order items, once collected, will correlate to the packing slip and be ready for shipment. The packer, who receives the order items and packing slip, will securely box the order, weigh it, and affix a shipping label to the package.

Throughout this process, the warehouse management and inventory software will guide through the tasks, alert on shortages, trigger reordering, and provide real-time inventory and order updates that affect the workflow of the other employees and departments.

Shipping orders to your customers may not be as simple as it sounds. The shipping terms could vary widely depending on your contractual relationships with each customer.

Are you covering the cost of shipping? Or are you using your carriers and then billing your customers for the charges?

Perhaps you’ve arranged to split the cost of shipping with your customers. No matter how complex your shipping terms are, and even if you have different terms for customers, your warehouse management software must handle them. Your workers must be able to see all relevant and appropriate information within the system so that accounting errors do not occur.

No matter the terms, as part of your customer service courtesy, once an order ships, your warehouse management system should automatically send out an electronic confirmation to the customer or an in-store or curbside pickup reminder that includes shipment tracking information.

Eliminate warehouse inefficiencies by utilizing fulfillment logistics settings within the inventory software. You want warehouse and inventory software that is both customizable and pre-structured with an intuitive interface.

This way, your workers can speed through inputting and updating the management system as they track and fulfill orders.

Providing fast, effective, and satisfactory customer service will require accurate, instantly accessible reporting. Setting different access levels for your staff may be appropriate, but your warehouse management software should be customizable in this way.

Depending on which employees you grant access to, your warehouse reports will let the viewer review and track inventory at all locations.

Reporting will cover four main categories. These are transfer reports, purchasing reports, receiving reports, and other warehouse reports.

The available reports should be as complex as your business. For your internal operations, the reports should also include inventory forecasting so that you can foresee and pre-plan your inventory to meet the needs of your business customers.

With the software, you can also review your employees’ productivity and specific details, such as who has completed safety training and who is licensed and certified.

To improve your warehouse’s efficiency, tracking the movement of all the goods is essential. Integrating RFID tags and barcodes is the most effective way to do this.

RFID and barcodes can give complete information about the product – inventory count, placements, location, real-time data, etc.

This makes inventory barcode scanners and RFID integration extremely important as it helps reduce manual data entry errors.

POS integration has proven to be a vital tool for businesses. POS records customers’ data, their preferences, purchases, etc.

Fusing the POS data with warehouse data will ensure a much better selection of goods and services. It will give an idea of purchasing patterns and product reviews, thus affecting the restocking of goods.

Moreover, integrating your retail POS software with the warehouse management system can help personalize the product offerings and improve the customer experience.

Warehouse management system benefits outline the importance of an efficient WMS and how it can help simplify B2B operations:

Wondering how to simplify the order fulfillment complexity? Here are some sure-shot ways:

Manage numerous orders effectively by selecting products for several orders simultaneously. Thus, boosting output, reducing time, and increasing efficiency. It helps with:

Pallet and container management helps increase the storage capacity, expedites the handling procedure, and enhances the picking process. A few of the advantages are:

Streamlining the process and having complete visibility of the product movement is crucial. Here are some ways to do this:

This helps track various products using distinct serial numbers. A few of the advantages are:

Demand prediction, inventory optimization, and replenishment process automation are achieved by leveraging data analytics and historical trends. It helps with:

Warehouse management software helps reduce costs and optimizes productivity. Here’s how:

Effective warehouse layouts and optimum storage reduce storage costs. Here are some of the benefits:

Implementing automation, robotics, and efficient workflows to reduce manual labor requirements. The benefits are:

Integration is an essential tool to help grow business operations. It reduces manual jobs, thus giving more time and energy towards expansion. Here’s how integration can help:

WMS ensures that our customers have access to up-to-date information regarding their orders. This includes the status of their orders, inventory levels, and shipment tracking details. A few of the benefits are:

Integrating B2B e-commerce platforms with warehouse systems is advisable to ensure real-time data synchronization. It benefits with:

The future of B2B warehouse management systems (WMS) is set for significant change due to technological advances. Moreover, the evolving business requirements also factor in the future of WMS integration with the latest technology.

Here are some key aspects of the future of WMS in the B2B sector:

WMS can leverage emerging technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT). AI and ML algorithms are well-known to automate manual tasks, enhance decision-making processes, provide predictive analysis, and optimize workflows for better inventory management.

WMS will provide real-time visibility into inventory movements, order statuses, and overall warehouse performance. It will also utilize technologies like RFID and blockchain to offer advanced traceability features, ensuring end-to-end transparency in the supply chain.

Cloud-based warehouse management system (WMS) solutions are becoming increasingly popular due to their scalability, flexibility, and accessibility. Cloud technology makes it easier to integrate with other systems, enables remote access, and ensures seamless operations.

Automation and robotics in warehouses are expected to increase in the future. Autonomous mobile robots, robotic picking systems, and automated guided vehicles will become more critical in making order fulfillment processes more efficient, reducing labor costs, and improving overall efficiency.

AR and VR technologies are set to revolutionize B2B warehouses. With their ability to provide visual cues and instructions, these technologies will significantly enhance order-picking accuracy, reduce training time, and increase workforce productivity.

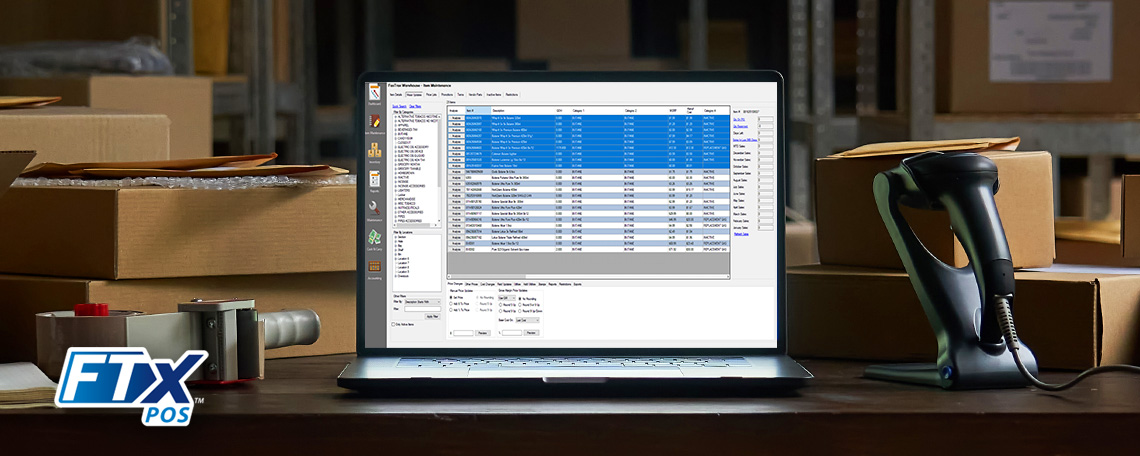

Strong B2B customer service is critical to the health and longevity of your warehouse. FTx Warehouse can accurately track your inventory and automate your daily warehouse operations.

Our premium software solutions will give you complete control over your inventory, provide location picking, and equip your workers with the ability to look up and modify item information right from the warehouse floor.

With EDI support built into our software, you can electronically accept orders through the file system or FTP, send out invoices electronically to customers, and mass-print your EDI orders for easy and efficient picking.

Our Warehouse Prime features also include:

If you would like to learn more and get started with FTx Warehouse, you can contact us anytime.

WMS forecasting uses historical data and algorithms to accurately:

Yes. Modern warehouse management systems (WMS) efficiently handle complex B2B orders and can:

Warehouse Management System (WMS) can improve delivery time and customer satisfaction by:

This leads to faster order fulfillment and improved delivery times, thus increasing customer satisfaction.

Yes, it may be a bit expensive, but the benefits outweigh the costs. WMS offers streamlined operations and works more efficiently than manually managing the warehouse.

The perfect WMS for a B2B business depends on its specific operational needs. Many B2B companies benefit from cloud-based WMS platforms that offer flexibility, integration capabilities, and industry-specific features.

Yes. WMS implementation in B2B warehouses can lead to significant cost savings. It reduces manual labor, automates processes, optimizes workflows, and improves inventory accuracy, enabling companies to allocate resources more efficiently.

Learn more about this topic. See these related posts on the FTx POS blog.

Managing a multi-location retail business brings a host of challenges. From keeping operations streamlined across…

Read More >>Retail marketing in 2025 isn’t just about making sales; it’s about creating unforgettable customer experiences…

Read More >>A vape shop can be exciting to start, but managing the financial end of it,…

Read More >>