Everything You Need to Know About Holiday Returns and Gift Card Fraud Prevention

Oct 31, 2025 | 12 Min Read

Inventory control isn’t a glamorous topic. But it’s the silent engine powering countless successful companies.

If you don’t have a handle on your warehouse’s inventory control, your business may stumble. Unfortunately, inventory control isn’t easy to fix. It requires a delicate balance between having enough stock to meet demand without drowning in unsold units.

OK, but what exactly is inventory control?

First, inventory control differs from inventory management. Inventory control, in its simplest form, focuses only on physical inventory. It’s the process of managing the flow of goods through a business.

Therefore, a store inventory control process would include tasks like purchasing, receiving, and storing products, and successful inventory control would tell you exactly how much of an item you have on hand at any given moment. Inventory control’s aim is to have the right amount of the right product at the right time.

IBM states that 56% of retail business leaders claim that their inventory information is not accurate. Does this ring a bell? It’s time to eliminate inefficiencies and streamline your operations. Get in touch to see how we can help!

You’re here because you want to improve the inventory control procedure. And this article offers a deep dive. Keep reading to learn:

The aim of retail inventory control is to have the right amount of stock to meet customer demand. This isn’t easy, especially if your warehouse juggles thousands of SKUs. Inventory control helps to solve this problem by:

Ultimately, inventory control helps to prevent stockouts and overstocking and maximizes revenue through reduced carrying costs and less waste.

Inventory management isn’t a static task; it’s a dynamic process that demands precision and foresight. In a marketplace where efficiency dictates success, simply “keeping track” isn’t enough. You need strategic control. Let’s explore practical methods to achieve that, moving beyond rudimentary approaches.

While often dismissed as archaic, manual tracking offers a level of tangible control that digital systems can’t replicate. It’s not just about writing things down; it’s about understanding the flow of goods through physical engagement.

Inventory stock cards offer a granular view of individual item movement, providing a detailed audit trail.

Spreadsheets bridge the gap between manual tracking and sophisticated software, offering a structured approach to inventory management.

Entry-level inventory software provides automation and streamlined workflows, freeing up valuable time and resources.

Inventory control is not the same as inventory management. They’re often used interchangeably, but the focus of inventory control is much narrower than inventory management.

Inventory control refers to the organization, tracking, and management of physical inventory. In a nutshell, store inventory control is “stock control.” Its core purpose is to accurately manage physical units and move them through the business.

For example, inventory control might include tasks like:

Inventory management, however, includes retail inventory control. But it also includes aspects like forecasting and planning. In other words, inventory control is one aspect of inventory management, which encompasses everything related to inventory.

Inventory management, for example, includes store inventory control as well as tasks like:

Also, implementing effective inventory management techniques will not only optimize your Stock control processes but also maintain a professional and organized receiving environment, ultimately contributing to a smoother and more efficient business operation.

Ultimately, inventory management software typically provides automation and tools to facilitate better inventory control and management. It also helps to improve B2B customer service. Some of the features you would need include:

Maintaining optimal inventory levels is critical for businesses – a misstep can lead to lost sales, wasted resources, and unhappy customers.

Here are some of the key obstacles that businesses face in the world of warehouse inventory control:

Demand forecasting is often predictable and prone to sudden shifts. Seasonality, trends, and economic fluctuations can throw off forecasts. This leads to overstocking, slow-moving inventory, or stockouts of popular products.

Getting better forecasts starts with improving retail inventory control procedures. Accurate and consistent inventory counts and real-time inventory data help make inventory forecasts more accurate.

Controlling physical inventory requires quality data. Unfortunately, inventory data is often inaccurate or incomplete. Missed counts, issues with data sharing (between locations), or mis-scanned items, for example, cause this problem.

Bad data creates a murky overall picture of inventory and hinders data-driven decision-making. A missed count, for example, is a fast way to overstock or understock an item.

Inventory visibility refers to tracking and viewing inventory in real-time. However, in businesses with complex supply chains or large warehouses, limited visibility is a real problem. Lost or misplaced inventory translates to lost time and money.

For example, let’s say warehouse staff misplaced a pallet. They placed it behind several products and obscured it from view. This pallet is now unaccounted for and would skew any counts until it is found. Your inventory visibility would be limited.

Human error causes a lot of store inventory control issues. These errors are often made due to:

Inventory control procedures seek to address these issues by putting clear processes in place.

Delays, shortages, and price fluctuations can throw off forecasts and strain businesses. Inventory control solves this with reorder automation. This can reduce the need for last-minute ordering, significantly reducing delays.

Navigating these challenges requires a multi-pronged approach and the right tech tools. First, you must set efficient processes and organization for managing inventory.

Next, focus on utilizing technology to be more efficient. Automation, machine learning-driven forecasting, and multi-location syncing – all features in modern warehouse inventory control tools – will help you get a handle on your inventory faster.

Stagnant revenue can often be tied to poor inventory control. However, this connection isn’t always obvious.

Instead, you might notice your carrying costs (costs to store and handle inventory) going up, low inventory turnover rates, etc.

Therefore, it’s important to track and recognize these indicators of poor inventory control. Here are some reasons why inventory control is important:

1. Financial Drain: Carrying costs, markdowns, capital tie-up, and write-offs eat away at profits. Inventory turnover ratio is a great metric to track to better understand the financial impact of inventory.

2. Operational Chaos: Inefficient processes, inaccurate records, and increased employee workload hinder productivity and accuracy. A few metrics to watch include inventory and picking accuracy, as well as put-away cost.

3. Customer Frustration: Stockouts, backorders, and unreliable availability damage brand loyalty and lead to lost sales. You can get a sense from customer reviews and feedback, but also be aware of your on-time delivery rate and packing accuracy.

4. Environmental Footprint: Excess waste and increased transportation contribute to a larger carbon footprint. You might watch metrics like cardboard and packing waste or delivery efficiency.

5. Missed Opportunities: Tied-up capital limits growth potential, and inaccurate forecasts hinder informed decision-making. One small business KPI to consider would be the inventory-to-working-capital ratio, which shows how much capital is tied up in inventory. An ideal rate would be 1:1; if you are over 2:1, you likely have an opportunity to improve.

These costs can quickly add up. Therefore, you need inventory management tools that put data at your fingertips. Once you’ve established a baseline, you can begin to make improvements.

Fortunately, there are some fast ways to overcome inefficient inventory control.

Maximizing inventory control requires a multi-pronged approach, and it will differ depending on the business type and industry. However, there are some tactics that apply to all businesses.

Here are some ideas to improve inventory control:

A strong inventory control plan starts with accurate inventory data. You can then use this to build your inventory optimization plan. You might try:

ABC Analysis categorizes inventory based on both its financial value and its sales velocity, classifying items as A (high-value, fast-moving), B (moderate), and C (low). This classification is a practical application of the 80/20 rule, also known as the Pareto Principle, which posits that approximately 80% of your sales revenue is often generated by just 20% of your inventory items.

Consequently, management of “A” items is paramount. These items, representing a smaller portion of your inventory, have a disproportionately large impact on your profitability. This necessitates precise tracking, accurate demand forecasting, and well-maintained safety stock levels to prevent costly stockouts.

Conversely, “C” items, which contribute less to revenue, can be managed with streamlined processes, reducing storage costs and freeing up resources for the more critical “A” items. This strategic approach to inventory management, guided by the 80/20 rule and implemented through ABC analysis, allows for optimal resource allocation and enhanced overall efficiency.

Use your historical data to build advanced demand forecasts. Inventory control systems typically include machine learning-driven forecasting, which can greatly reduce time and human error.

Maintain a buffer stock (safety stock) for A items to prevent stockouts during unexpected demand surges. Regularly review and adjust these levels based on lead times and supplier reliability.

By using these formulas, you can have a better grasp on when and how much to reorder.

Technology is 100% a necessary tool to get better at inventory control. Some of the tools you will need include:

There are many different approaches to inventory control. Just-in-Time, FIFO, and LIFO are some of the methods you can use. Here’s a look at some processes you can implement:

Inventory control doesn’t just happen in the warehouse. There should be synergy between all areas of the business, from sales and marketing to purchasing and operations.

Clear Communication: Establish clear communication channels between purchasing, sales, and operations to ensure everyone is aligned on inventory needs and forecasts.

Demand Collaboration: Encourage sales and marketing teams to share insights on upcoming promotions and potential demand shifts to inform inventory planning.

Finally, inventory control isn’t a set-and-forget process. Shifts and changes in demand will always require continual improvement.

Ultimately, inventory control software automates many tasks that can help you stay ahead of your stock levels by optimizing your warehouse layout system and process. Some must-have features include:

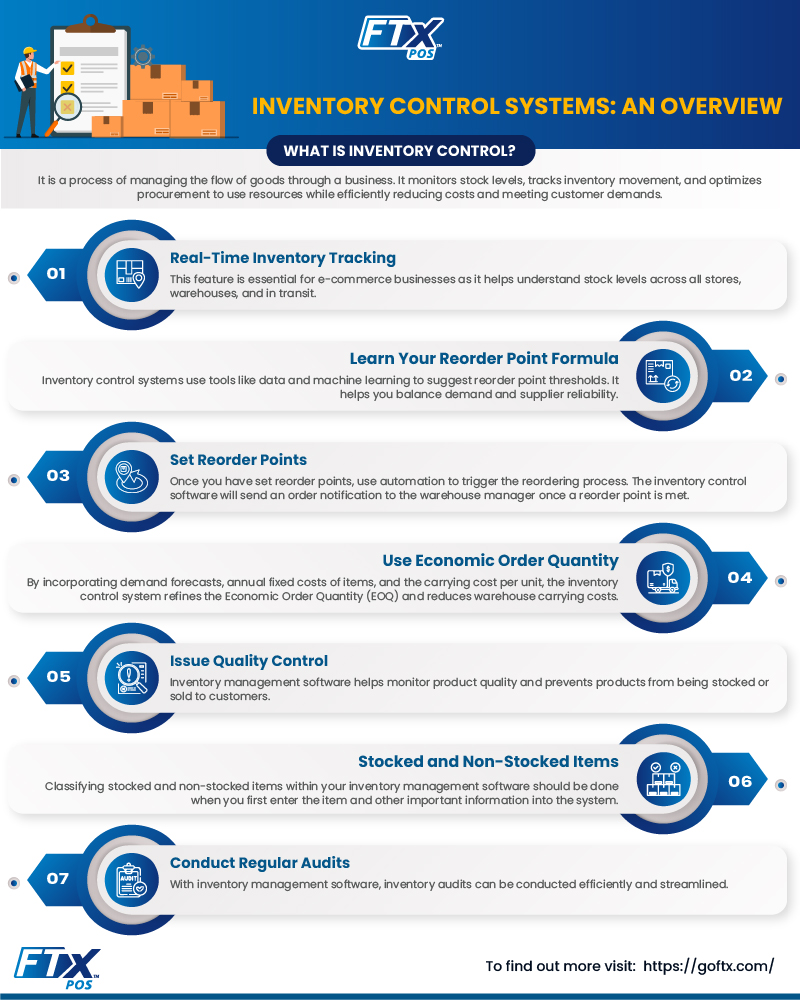

Real-time inventory refers to understanding your stock levels across the entire operation – retail stores, warehouse, in-transit – at any moment. Real-time inventory is especially necessary for businesses that do ecommerce.

The reason: You need to update your website regularly so that your storeroom, retail brick-and-mortar shops, website, and warehouse all show accurate data.

For example, without it, you would have to manually sync inventory data, which is time-consuming and leads to a lot of errors.

For real-time inventory tracking, you need two tools: barcode scanners and radio-frequency identification (RFID) tags. These make it possible to scan inventory at the register or the warehouse and sync that data instantly.

Interesting Read: Warehouse Inventory Counting Techniques: Tips for Better Accuracy

Maintaining accurate inventory control requires you to balance demand and supplier reliability. To balance the two, you need to understand the reorder point for every product in your database.

A reorder point is an item’s minimum quantity that triggers automatic replenishment. Inventory control tools use data and machine learning to suggest reorder point thresholds.

Par levels represent the minimum quantity of inventory that should be kept on hand at all times. When inventory levels fall below the par level, a reorder is triggered.

Once you’ve estimated a reorder point, you can use automation to trigger the reordering process. This greatly reduces the risk of human error and oversight.

Orders would still need to be accepted. For example, using inventory control software, once a reorder point was met, an order notification would be sent to the warehouse manager. The manager could then accept the order and process it.

“The economic order quantity, or EOQ, refers to the optimum stock level the warehouse should maintain. Again, for a warehouse managing thousands of SKUs, this process is time-consuming. This is a distinct method from inventory valuation methods like FIFO/LIFO/FEFO.

Software automates the EOQ process. They use data like demand forecasts, annual fixed costs of items, and the carrying cost per unit to fine-tune the EOQ. This can greatly reduce carrying costs for warehouses. It’s important to carefully assess and implement appropriate stock rotation methods (FIFO/FEFO/LIFO) based on your specific inventory needs, as these methods address the flow of goods and cost accounting, while EOQ focuses on optimal order quantities.”

The quality of products is important to monitor, and software makes it easier. During regular cycle counts or doing a warehouse-wide QC assessment, you can mark products that fail QC as “On Hold.” This will prevent the product from being stocked or sold to customers.

Accurately differentiating between items that are “stocked” versus “non-stocked” is one of the most critical aspects of inventory control. These terms have nothing to do with whether an item is housed in your warehouse. Rather, these are accounting terms that will ultimately simplify your financials and reporting.

A “stocked” item refers to a traditional inventory item that will reflect on your company’s balance sheet as an asset. A “non-stocked” item, because it’s typically “bought and sold” quickly, will impact your company’s profit & loss statement as either an expense or (cost of goods sold (COGS).

Designating the classification “stocked” or “non-stocked” to each inventory item within your software should be done when you first enter the item, along with all its pertinent information, into the system.

Performing regular audits is another important process for managers that want to maintain inventory control at their warehouse. Warehousing high levels of inventory stock generally leads to overstocking, an unnecessary expense that impacts cash flow.

Measurable costs are associated with shelving items, and depending on whether those items are classified as “stocked” or “non-stocked,” your financial reporting could end up appearing inaccurate.

The key is to only warehouse an optimal quantity of each item, not too much and not too little. Your inventory management software is your best tool for conducting inventory audits in an efficient, streamlined manner.

Choosing inventory management software isn’t an easy decision to make. But it’s critical for gaining control of your inventory, reducing costs, and improving warehouse customer service. This is especially true as your business scales.

FTx POS is a cloud-based solution that includes a variety of warehouse management tools that are designed to help multi-location retailers succeed. Our warehouse management software includes:

Reach out to us today to get started with FTx Cloud POS for $0 and enjoy low processing fees plus powerful tools to streamline your business!

Inaccuracy leading to stockouts and overstocking, slow picking and packing times, inefficient layouts wasting space, lack of automation hindering productivity, and even theft impacting stock levels.

Start by assessing your current processes. Identify bottlenecks, areas with high error rates, and inefficient workflows. Then, choose relevant strategies like barcode scanners, cycle counts, or layout optimization based on your specific needs. Implement changes gradually, monitor results, and adjust as needed.

Warehouse Management Systems (WMS) provide a centralized platform for managing inventory data, streamlining processes, and optimizing picking routes. Barcode scanners and RFID tags improve picking accuracy and real-time tracking. Automated storage and retrieval systems (ASRS) can significantly boost efficiency and space utilization.

The frequency depends on the value and demand of your items. High-value or fast-moving items might need monthly counts, while slower-moving ones could be counted quarterly. A risk-based approach helps prioritize the most critical items.

Implement clear labeling and zoning in your warehouse for easier item identification and navigation. Conduct regular staff training on proper inventory handling procedures. Leverage forecasting tools to anticipate demand and optimize stock levels. By addressing these basic areas, you can see noticeable improvements in accuracy and efficiency.

Remember, continuous improvement is key. Regularly re-evaluate your processes, adapt to changing needs, and embrace new technologies to keep your warehouse inventory control sharp.

Oct 31, 2025 | 12 Min Read

Apr 8, 2025 | 13 Min Read